Ranco designed its roller conveyor with one purpose in mind: to provide a premium finished product using premium components and superior design and workmanship.

Ranco roller conveyors are built to stand the test of time. Hands down, we build the heaviest duty conveyors in the industry.

Our standard conveyor design includes many options not found on other conveyors. Cema C 5” diameter rollers are standard. Our return rollers are not the solid steel drum, but rather rubber disk rollers that fight against build up and aid in belt tracking.

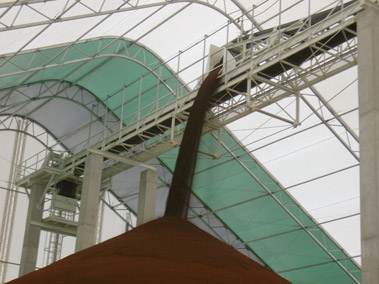

The conveyor frame itself is constructed of 12” extruded steel channel that weighs 20.7 lbs/foot. Thanks to this channel Ranco conveyors will last for years, even in corrosive environments like fertilizer storage buildings. We also have the capability of producing stainless steel formed 12” channel.

Our standard pulleys are premium spiral wrapped close wing pulleys. The spiral wrapping greatly reduces the noise associated with operating a conveyor. Spiral pulleys also increase belt life as they don’t cause the repeated impact on the belt that a standard wing pulley does.

Ranco’s roller conveyors are available from 24” wide up to 42” wide and can handle up to 1,200 tons per hour. They can be utilized in many parts of your operation; receiving, transfer, or overbin.

- 5” diameter troughing idlers on 4’ centers

- 5” diameter rubber disc return rollers on 10’ centers

- Premium quality spiral wrapped pulleys used throughout

- Heavy-duty 12” mild steel channel frame or formed stainless steel

- Mild steel sandblasted, primed, with polyurethane finish

- Capacities up to 1,200 TPH

- Two way trippers available on overbin units

- Ranco built support towers and catwalks

We are able to downgrade some options to decrease the investment cost at the customer’s request.