DW Series I Blenders

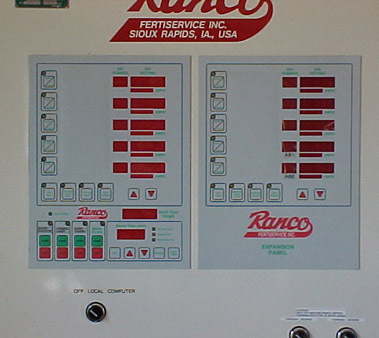

Originally developed and introduced to the industry in 2002 by Ranco is the Multi-Blender Declining Weigh blend system, combined with the newest MeshDCS wireless operating system, also introduced exclusively by Ranco. This ‘DW’ declining weigh system weighs the output of each product as it’s blending and continually adjusts every few seconds throughout the run for any variability caused by density or flowability changes.

If the output varies by more than ½ pound, an adjustment is automatically made to the speed of the meter unit to compensate for this variance. To maintain a ‘non-stop’ operation, the bins can be filled while the system is blending. As the end loader fills the bin, and the blender is running, it suspends the declining weight measuring and continues to dispense product in volumetric mode. Once the control panel senses the end loader has completed that pour, the DW technology resumes and immediately checks the output for any necessary meter unit adjustments, + or – to provide extremely accurate final loads.

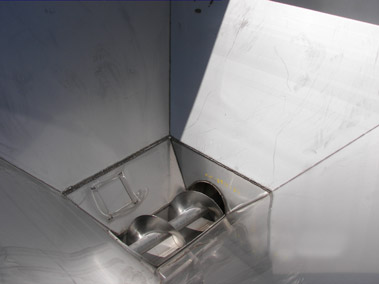

The bins and support framework are constructed entirely of 304 stainless steel and each bin is mounted on four stainless steel load cells. The load cells, combined with the digital LED control panel, the declining weigh technology, and the MeshDCS wireless operating system, control the output of product of the metering unit under each bin. This is the ultimate in speed, efficiency and accuracy in this industry.

- All 304 stainless steel construction in Series I and Series II size bins

- Various bin sizes up to 14′ wide

- Declining Weigh technology – automatically adjusts for density changes

- MeshDCS wireless operating system

- Computer interface compatible

- Optional touch screen controls

- Continuous flow – no batching like conventional mixers

- True through-put capacities – up to 300 TPH

- Unsurpassed speed and accuracy

- Easily expandable – can add bins for future products

- Blend faster – can convert meter screws to drag chain meter units to increase speeds

Ranco blender bins have sufficient slope and do not require vibrators to keep product flowing in each bin. Vibrators are an added expense that increase maintenance and lead to pre-mature bin failure.

DW Series II Blenders

The DW Series II blender bins are designed to fit into a smaller footprint than the Series I bins for those who wish to upgrade from an existing Ranco volumetric blender. The Series II hoppers allow you to install a declining weigh blend system in the same space as your current volumetric blender. Generally, no pit or building modifications are necessary. Same as the Series I blender bins, the Series II declining weigh system weighs the output of each product as it’s blending and continually adjusts for any variability caused by density or flowability changes.

If the output varies by more than ½ pound, an adjustment is automatically made to the speed of the meter unit to compensate for this variance. To maintain a ‘non-stop’ operation, the bins can be filled while the system is blending. As the end loader fills the bin, and the blender is running, it suspends the declining weight measuring and continues to dispense product in volumetric mode. Once the control panel senses the end loader has completed that pour, the DW technology resumes and immediately checks the output for any necessary meter unit adjustments, + or – to provide extremely accurate final loads.

The bins and support framework are constructed entirely of 304 stainless steel and each bin is mounted on four stainless steel load cells. The load cells, combined with the digital LED control panel, the declining weigh technology, and the MeshDCS wireless operating system, control the output of product of the metering unit under each bin. This is the ultimate in speed, efficiency and accuracy in this industry.

- All 304 stainless steel hoppers, meter tubes, and meter screws

- Various bin sizes starting at 5 1/2′ wide

- Stainless steel load cells and stand assemblies

- Specially designed to fit in the same space as our volumetric blenders

- Direct drive – no chain or sprockets

- Declining weigh technology – automatically adjusts for density changes

- MeshDCS wireless operating technology

- Computer interface compatible

- Continuous flow – no batching like conventional mixers

- Unsurpassed speed and accuracy

- Expandable – can add bins for future products

- Blend faster – can easily convert single screws to doubles

Ranco blender bins have sufficient slope and do not require vibrators to keep product flowing in each bin. Vibrators are an added expense that increase maintenance and lead to pre-mature bin failure.